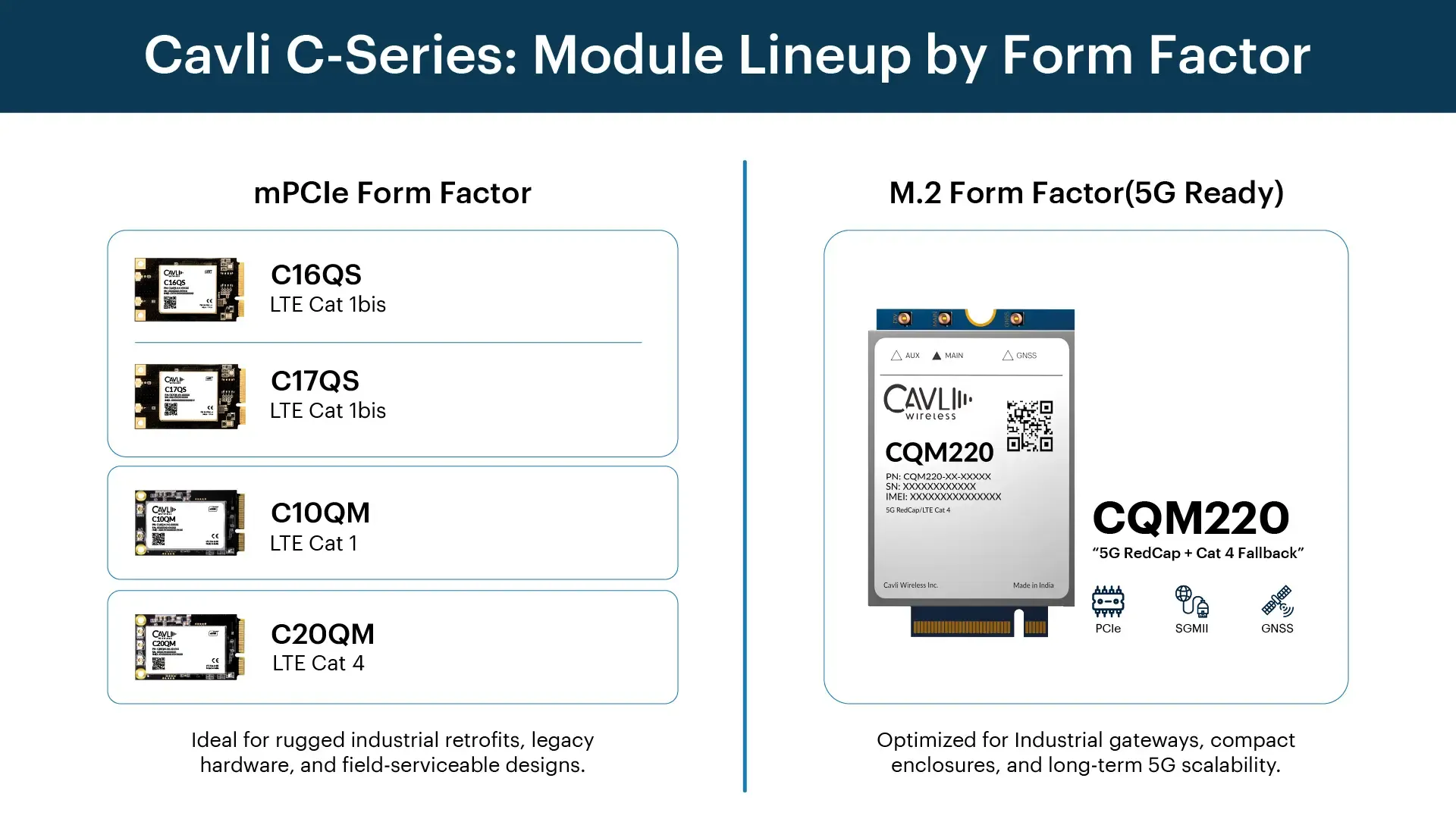

Industrial IoT design is no longer only about picking the right cellular technology. The hardware form factor you choose for the modem determines how your router, gateway, or controller scales, how easily it can be serviced in the field, and its readiness for the next generation of networks. Cavli Wireless supports both major modem form factors for industrial IoT deployments - M.2 and mPCIe.The M.2 line is anchored by the CQM220 5G RedCap platform, which brings Cat 4 fallback, PCIe Gen 2.0, SGMII, and multi-constellation GNSS in a compact footprint, while the mPCIe family covers the LTE tiers with C16QS and C17QS for Cat 1bis efficiency, and C11QM, C10QM, and C20QM for LTE Cat 1 and Cat 4 deployments.

Why Form Factor Choice Matters in Industrial Networking?

Industrial deployments are housed in outdoor cabinets, factory control panels, trackside enclosures, and compact DIN rail boxes. Thermal load, shock, vibration, and dust ingress are daily realities. Form factor is often the most practical lever for balancing performance against environmental stress. Larger mini PCIe cards offer more board area for copper pour, improving heat spreading, and can be mounted in robust sockets suited for heavier cabling and higher transmit duty cycles. Compact M.2 cards allow denser layouts and shorter signal paths, which is valuable for compact, high-performance routers.

Scalability and lifecycle are also tied to form factor. A mini PCIe slot has become a kind of “industrial-standard connector” for 4G modems in routers and gateways, so OEMs that already ship mini PCIe-based products can move from the Cat 1bis C16QS to the Cat 4 C20QM or the Cat 1 C10QM without redesigning the carrier board. In contrast, M.2 is gaining traction as the preferred connector for 5G-class performance, where PCIe Gen 2 from CQM220 can be routed cleanly to application processors. Performance and power expectations are tightly linked to the silicon on each card. Mini PCIe families like the C10QM and C11QM handle Cat 1 workloads with modest power envelopes, while the C16QS delivers Cat 1bis efficiency with aggressive power-saving features for metering and tracking. On the M.2 side, the CQM220 targets applications that require 5G RedCap throughput with PCIe and SGMII interfaces, while still operating reliably across industrial temperature ranges.

Engineering Implications: M.2 vs mPCIe

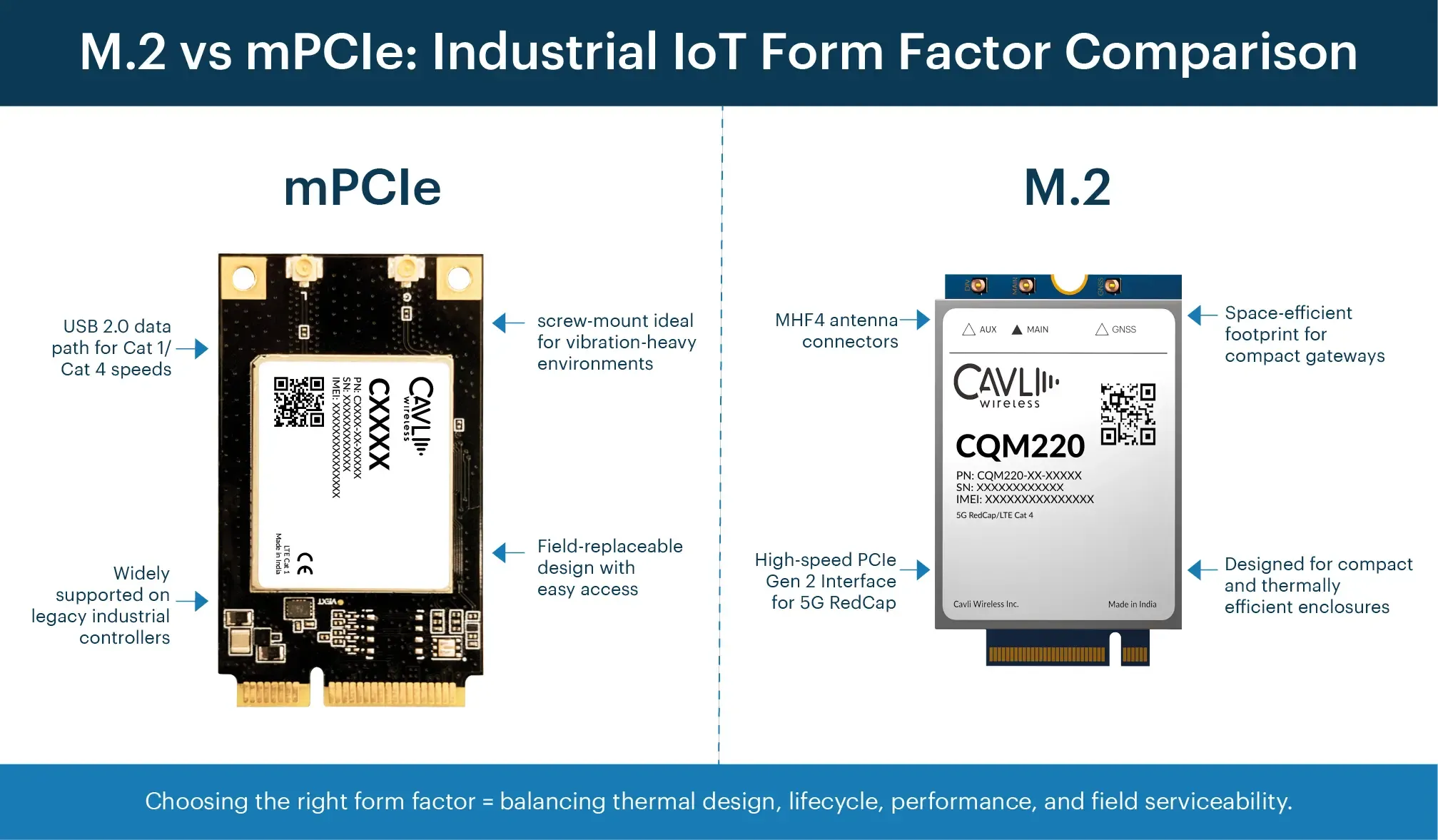

The electrical architecture of the two form factors represents a shift to a new generation of technology. The mPCIe standard, used by Cavli’s C10QM and C20QM series, typically utilizes a USB 2.0 interface for the modem's data path, despite using a PCI Express physical connector. This is standard for LTE Cat 1 and Cat 4 speeds, where USB 2.0 provides sufficient bandwidth. These modules also commonly expose UART interfaces and SIM signals directly through the edge connector, simplifying designs for legacy industrial controllers that rely on serial communication.

In contrast, the M.2 form factor is designed for high-speed signaling. While it supports USB 2.0 and 3.0, it is natively optimized for PCIe lanes. This makes it ideal for 5G RedCap-class modules such as the Cavli CQM220, which leverages the form factor to deliver a PCIe Gen 2 interface, crucial for supporting higher throughput with lower latency. This shift impacts board design; M.2 requires careful attention to high-speed differential pair routing and EMI shielding to maintain signal integrity at 5G frequencies, whereas mPCIe integration is often more forgiving in simpler PCB layouts.

Mechanically, the two standards offer different advantages. The mPCIe cards are larger and robust, using a screw-down mounting mechanism that is exceptionally resistant to vibration, a key feature for heavy machinery and automotive applications. The larger surface area also aids in thermal dissipation, which is beneficial for the C20QM (Cat 4) and C10QM (Cat 1) modules when operating in high-temperature enclosures.

The M.2 standard, as seen with the CQM220, offers a more compact footprint, particularly in length and thickness, allowing slimmer device profiles. However, M.2 modules often use a card-edge connector that, while secure, may require additional retention mechanisms in high-vibration settings compared to the dual-screw standard of mPCIe. In addition, antenna routing on M.2 cards is highly standardized, often featuring smaller IPEX MHF4 connectors compared to the larger U.FL connectors common on mPCIe, which requires greater precision during assembly.

For gateway builders, the real advantage shows up in the field. Teams often manage sites spread across wide, hard-to-reach areas, and rely on hardware that behaves predictably even when power, coverage, and climate work against them. With mPCIe builds, customers describe the experience as similar to using equipment that quietly takes care of itself. A C16QS-based gateway sips power and wakes reliably, C10QM and C11QM add location or voice when needed, and C20QM handles heavier data bursts without forcing redesigns. When a module needs swapping, technicians can replace it in minutes and move on.

Edge gateways follow a similar pattern. Builders who use compact M.2 designs often compare it to upgrading from a basic tool to a smarter one that helps carry the workload. The CQM220 gives enough headroom to run nodal analysis locally, and the fast PCIe and SGMII links keep data flowing smoothly to the main computer. This lets them build palm-sized gateways that still have room for I/O and application logic. The result is equipment that stays dependable, cuts down field visits, and keeps operators focused on the job instead of the hardware.

Customer Implications: M.2 vs mPCIe

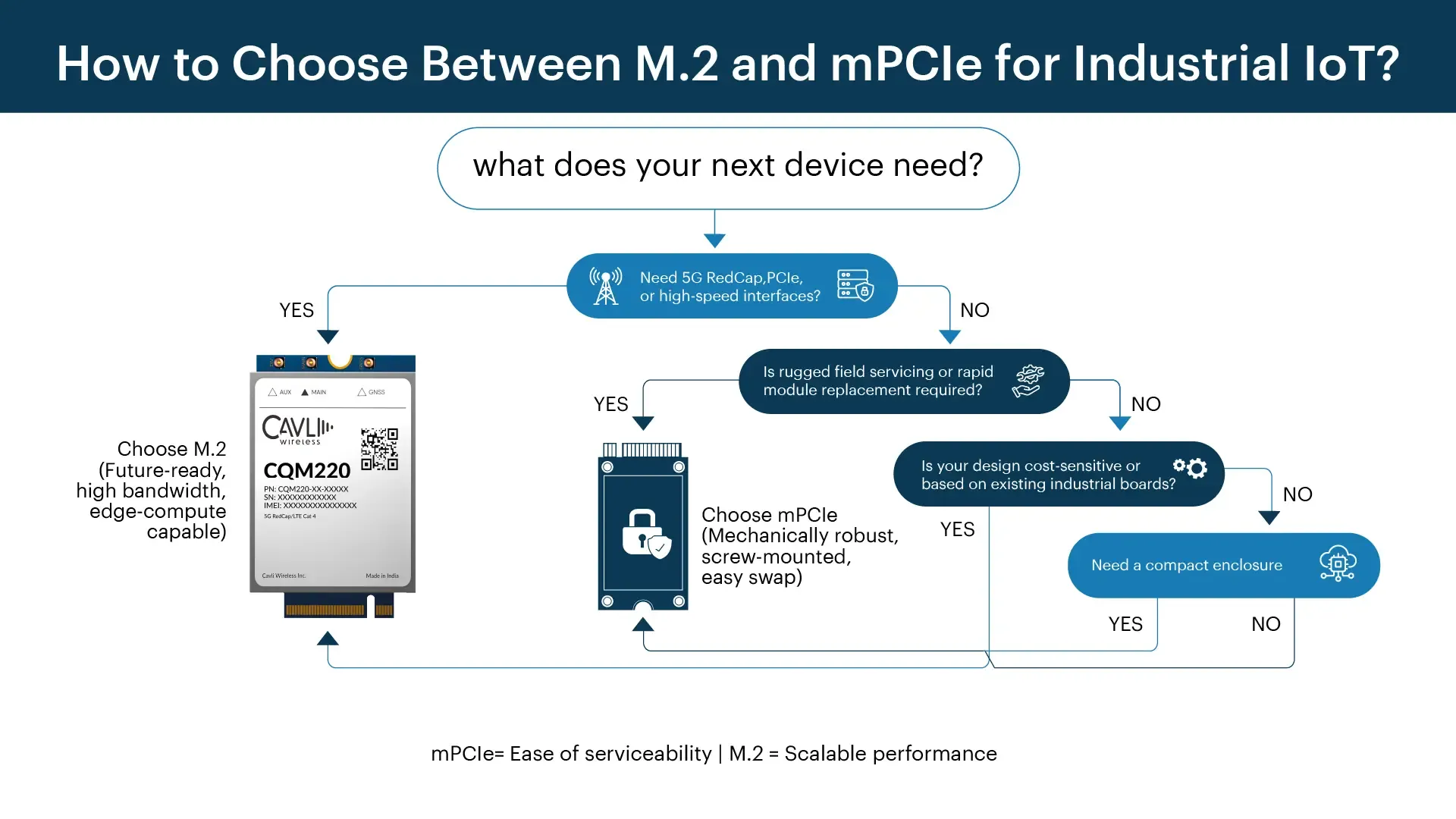

From a cost perspective, mPCIe modules like the C16QS and C17QS (LTE Cat 1bis) offer a highly economical solution for cost-sensitive deployments. The widespread availability of mPCIe sockets on legacy industrial boards allows these modules to be integrated with zero additional NRE (Non-Recurring Engineering) costs for connectors or adapters. In contrast, CQM220 and the broader M.2 ecosystem generally target higher-performance tiers. While the initial BOM cost might be higher due to the 5G RedCap technology and M.2 connectors, the power efficiency and longevity of 5G networks can lower long-term operating cost. The CQM220’s 5G RedCap architecture is designed to provide near-5G capabilities at a price point closer to LTE, effectively bridging the gap; however, the M.2 form factor itself signals a move toward a premium, future-ready product tier.

For field technicians, the mPCIe form factor is familiar and predictable. The robust screws and larger antenna connectors make field replacement of a C11QM or C20QM module straightforward, even with gloved hands in a roadside cabinet. The hot-swap capabilities (if supported by the host) and durable connectors are well-suited for maintenance-heavy industries.

M.2 modules are, on the other hand, designed for density. While replaceable, the smaller screws and delicate antenna connectors require more dexterity, making them better suited for factory installation or controlled maintenance environments rather than rugged field swaps. However, for devices requiring frequent upgrades to the latest cellular standards, the standardized M.2 keying ensures that the host device remains compatible with future module iterations.

In terms of ecosystem maturity and long-term viability, the mPCIe and M.2 standards now sit at different points in their lifecycle. The mPCIe ecosystem is mature but aging. While still dominant in industrial legacy systems, new high-speed chipset development is increasingly prioritizing M.2. Choosing mPCIe modules like the C10QM ensures backward compatibility with existing designs, extending the life of deployed assets. Conversely, M.2 is the forward-looking choice. Adopting the CQM220 allows manufacturers to market their devices as "5G Ready." It provides a clear upgrade path from LTE to 5G RedCap and beyond, ensuring that gateways deployed today will not become obsolete as carriers sunset older 4G bands in the coming decade.

For teams deploying industrial routers, the goal is simple: keep traffic moving even when the enclosure is hot, the cabinet is metal, and the signal is far from ideal. Customers often describe these routers as the “always-on anchors” of their sites, expected to terminate VPNs, push firmware, and stream telemetry without drifting offline. When they stick to established platforms, mPCIe feels like staying with a backbone they trust. C16QS and C11QM provide steady Cat 1bis and Cat 1 links, C20QM steps up to Cat 4 when more throughput is needed, and C10QM fits scenarios where GNSS, VoLTE, or broader I/O still matter. Technicians appreciate that they can swap modules quickly without disturbing the rest of the system.

Newer router designs follow a different path. Customers building compact, high-capacity units often compare the move to M.2 and the CQM220 to upgrading from a reliable workhorse to a smarter, faster tool that lightens the load. With PCIe or SGMII as the main WAN interface, these routers handle traffic bursts more smoothly and support on-device intelligence without extra hardware. This lets teams ship slimmer enclosures that stay responsive in the field and reduce the need for intervention. The outcome is predictable operation, reduced troubleshooting, and routers that continue delivering value long after deployment.

Conclusion

In the end, choosing between M.2 and mPCIe comes down to how you want your industrial IoT hardware to evolve and how your devices will be serviced over their lifetime. mPCIe delivers durability and straightforward field replacement that keeps legacy deployments running with minimal downtime. It remains the dependable choice for cost-sensitive routers and controllers that need predictable behavior in harsh environments. M.2 pushes forward with higher throughput, cleaner high-speed interfaces, and a roadmap aligned with 5G RedCap and future network upgrades. It enables slimmer, smarter gateways that can handle edge workloads without extra silicon. At its core, the decision follows a simple logic: pick mPCIe when reliability, ease of maintenance, and ecosystem maturity drive the design; choose M.2 when performance headroom, long-term scalability, and next-generation capability matter most.