James, Junior Network Engineer

Hey Adam, I’m diving into automotive computing lately. What exactly makes High Performance Computing (HPC) platforms so critical for modern vehicles?

Adam, Senior Network Engineer

Great question, James. Automotive HPC platforms power everything from ADAS to autonomous driving. They handle massive sensor fusion workloads from LiDAR, radar, and cameras while maintaining millisecond-level latency and ISO 26262 functional safety. Essentially, they serve as the central computing system inside the vehicle.

James, Junior Network Engineer

That sounds intense. How do these HPC systems manage such heavy workloads when dozens of sensors are constantly streaming data?

Adam, Senior Network Engineer

They rely on heterogeneous compute architectures where multicore CPUs, GPUs, NPUs, and DSPs operate in parallel. High-speed interfaces such as PCIe Gen4 and Gen5, GMSL, Automotive Ethernet, and MIPI CSI feed sensor data into the HPC cluster, enabling real-time perception and decision-making.

James, Junior Network Engineer

And with EVs and autonomous vehicles, how does the architecture evolve? I keep hearing about zonal compute and centralized domain controllers.

Adam, Senior Network Engineer

Exactly. Traditional ECUs are being replaced by zonal controllers that manage localized data, while a central HPC node coordinates vehicle-wide intelligence. This reduces wiring complexity, increases compute availability, and ensures ADAS, powertrain, and infotainment systems operate on a unified software-defined platform.

Opening Notes

The modern automobile has evolved into a distributed computing platform operating under extreme real-time and safety constraints. Advanced Driver Assistance Systems, autonomous driving stacks, connected infotainment, vehicle-to-everything communication, and electric powertrain management now rely on continuous high-speed data processing at the vehicle edge. This shift has driven the adoption of High Performance Computing (HPC) platforms as a core architectural requirement in automotive design.

Traditional vehicle architectures relied on dozens of isolated Electronic Control Units, each responsible for a specific function. As sensor counts increased and software complexity grew, this distributed model began to create latency bottlenecks, integration challenges, and limited scalability. High-performance computing platforms address these limitations by consolidating compute-intensive workloads into centralized or zonal compute nodes that are capable of handling parallel processing, artificial intelligence inference, and real-time decision-making.

Automotive HPC platforms are designed to ingest and process massive data streams from cameras, radar, LiDAR, inertial sensors, and vehicle networks while maintaining deterministic timing and functional safety compliance. These systems operate under strict thermal, power, and reliability constraints, often in harsh environments ranging from extreme cold to high vibration and sustained heat.

WHAT IS HIGH PERFORMANCE COMPUTING (HPC) IN AUTOMOTIVE SYSTEMS?

High-Performance Computing in automotive systems refers to the use of centralized or zonal computing platforms capable of executing computationally intensive workloads in real-time within a vehicle. These platforms integrate multi-core processors, hardware accelerators, and high-bandwidth interfaces to process large volumes of sensor data, run artificial intelligence models, and execute safety-critical control algorithms with deterministic timing.

Unlike conventional vehicle ECUs that perform narrowly defined tasks, automotive HPC platforms are designed to handle multiple domains simultaneously. This includes Advanced Driver Assistance Systems (ADAS), autonomous driving stacks, infotainment and human-machine interfaces, vehicle networking, powertrain optimization, and connectivity management. The goal is to consolidate distributed computing into fewer, more capable compute nodes that improve performance, scalability, and system integration.

Automotive HPC vs Traditional ECU Architectures

Traditional ECU-based architectures rely on many dedicated controllers, each optimized for a single function. While effective for earlier vehicle generations, this approach struggles with modern requirements such as sensor fusion, AI inference, and continuous software updates. Automotive HPC platforms replace this fragmented model with centralized compute that supports parallel execution and shared data access across domains.

HPC platforms enable tighter synchronization between perception, planning, and control tasks. This is critical for real-time decision making in scenarios such as collision avoidance, adaptive cruise control, and autonomous navigation, where latency and predictability directly affect safety.

Key Characteristics of Automotive HPC Platforms

Automotive HPC platforms are defined by several core characteristics:

- High compute density with multi-core CPUs and dedicated accelerators

- Support for heterogeneous processing, including CPU, GPU, NPU, and DSP workloads

- Deterministic real-time performance for safety-critical tasks

- Compliance with functional safety standards

- High-bandwidth data ingestion from cameras, radar, LiDAR, and vehicle networks

- Secure execution environments with hardware-level isolation and encryption

- Capability to support over-the-air software updates and long-term feature expansion

Role of HPC in Software-Defined Vehicles

In software-defined vehicles, functionality is increasingly delivered and upgraded through software rather than fixed hardware. Automotive HPC platforms act as the execution layer for this model. They provide sufficient compute headroom to support future software features, enable centralized orchestration of vehicle functions, and allow manufacturers to deploy updates, enhancements, and new services throughout the vehicle lifecycle.

By abstracting vehicle intelligence from individual ECUs, HPC platforms make it possible to standardize software stacks across vehicle platforms, reduce development complexity, and accelerate innovation without requiring hardware redesigns for most new features.

AUTOMOTIVE HPC ARCHITECTURE OVERVIEW

The architecture of HPC is optimized to handle real-time workloads, parallel data streams, and safety-critical execution within strict power and thermal limits.

At a high level, an automotive HPC platform consists of the following architectural layers:

- Sensor ingestion and vehicle network interfaces

- Heterogeneous compute engines

- Memory and data movement subsystems

- Safety and real-time execution framework

- Connectivity and software management stack

Each layer plays a critical role in ensuring deterministic behavior and scalable performance.

Sensor Ingestion and Data Interfaces

Modern vehicles generate high-volume data from cameras, radar, and LiDAR. Automotive HPC platforms must ingest and synchronize these streams with minimal latency to support real-time perception.

Key interfaces include:

- MIPI CSI or GMSL for camera inputs

- Automotive Ethernet or PCIe for radar and LiDAR data

- CAN, CAN FD, and FlexRay for vehicle control signals

The HPC platform timestamps and aligns incoming data to enable accurate sensor fusion. Any latency or data loss at this stage can directly affect safety-critical decision-making.

Heterogeneous Compute Engines

Automotive HPC platforms use multiple compute engines optimized for different workloads to meet real-time and power constraints.

Central Processing Units (CPUs)

Central Processing Units (CPUs) manage control logic, task scheduling, and overall system coordination

Graphics Processing Units (GPUs)

Graphics Processing Units (GPUs) accelerate parallel image processing, video pipelines, and graphical visualization

Neural Processing Units (NPUs)

Neural Processing Units (NPUs) execute artificial intelligence inference workloads for perception tasks and driver monitoring systems

Digital Signal Processors (DSPs)

Digital Signal Processors (DSPs) process incoming sensor signals and handle time-critical data such as radar and audio streams

Distributing workloads across specialized engines ensures predictable latency and power efficiency.

Memory Architecture and Data Movement

High-performance memory access is essential for sensor fusion and AI workloads.

- LPDDR5 or LPDDR5X provides high-bandwidth data access

- On-chip SRAM supports low-latency operations

- ECC-protected memory ensures data integrity

Efficient data movement using shared memory and direct memory minimizes latency and prevents processing bottlenecks.

Real-Time Execution and Functional Safety

Automotive HPC platforms must guarantee deterministic execution for safety-critical functions.

- Real-time operating systems schedule time-sensitive tasks

- Safety islands isolate critical workloads

- Lockstep cores and watchdogs detect faults

These mechanisms ensure compliance with functional safety requirements such as ISO 26262.

Connectivity and Software Management

HPC platforms support connected and software-defined vehicle architectures.

- 4G and 5G enable cloud connectivity

- Secure boot protects firmware integrity

- Over-the-air updates allow feature upgrades

These capabilities enable long-term scalability and lifecycle management.

Step-by-Step Workflow: How an Automotive HPC Platform Operates

Sensor Data Acquisition

Cameras, radar, LiDAR, and vehicle sensors continuously generate raw data. Camera frames arrive through MIPI CSI or GMSL, while radar and LiDAR data are delivered via Automotive Ethernet or PCIe. Control signals are received through CAN or CAN FD.

Time Synchronization and Buffering

All incoming sensor data is timestamped and buffered to ensure temporal alignment. Accurate synchronization is critical for sensor fusion and prevents inconsistencies between perception inputs.

Preprocessing and Signal Conditioning

DSPs and dedicated accelerators filter noise, normalize signals, and prepare raw data for higher-level processing. This stage reduces the compute load on AI and perception pipelines.

Perception and AI Inference

NPUs and GPUs execute neural network models to detect objects, lanes, vehicles, pedestrians, and obstacles. Outputs are generated in real time with deterministic latency.

Sensor Fusion

Perception outputs from multiple sensors are fused into a unified environmental model. This improves accuracy and reliability compared to single-sensor inputs.

Decision and Path Planning

CPU cores execute decision logic and planning algorithms based on fused data. The system evaluates vehicle state, surroundings, and safety constraints to determine the next action.

Control Signal Execution

Validated commands are transmitted to braking, steering, powertrain, and body control systems through real-time vehicle networks.

Continuous Feedback Loop

The entire process repeats continuously within strict timing budgets. Feedback from vehicle motion and sensor updates ensures adaptive and responsive behavior.

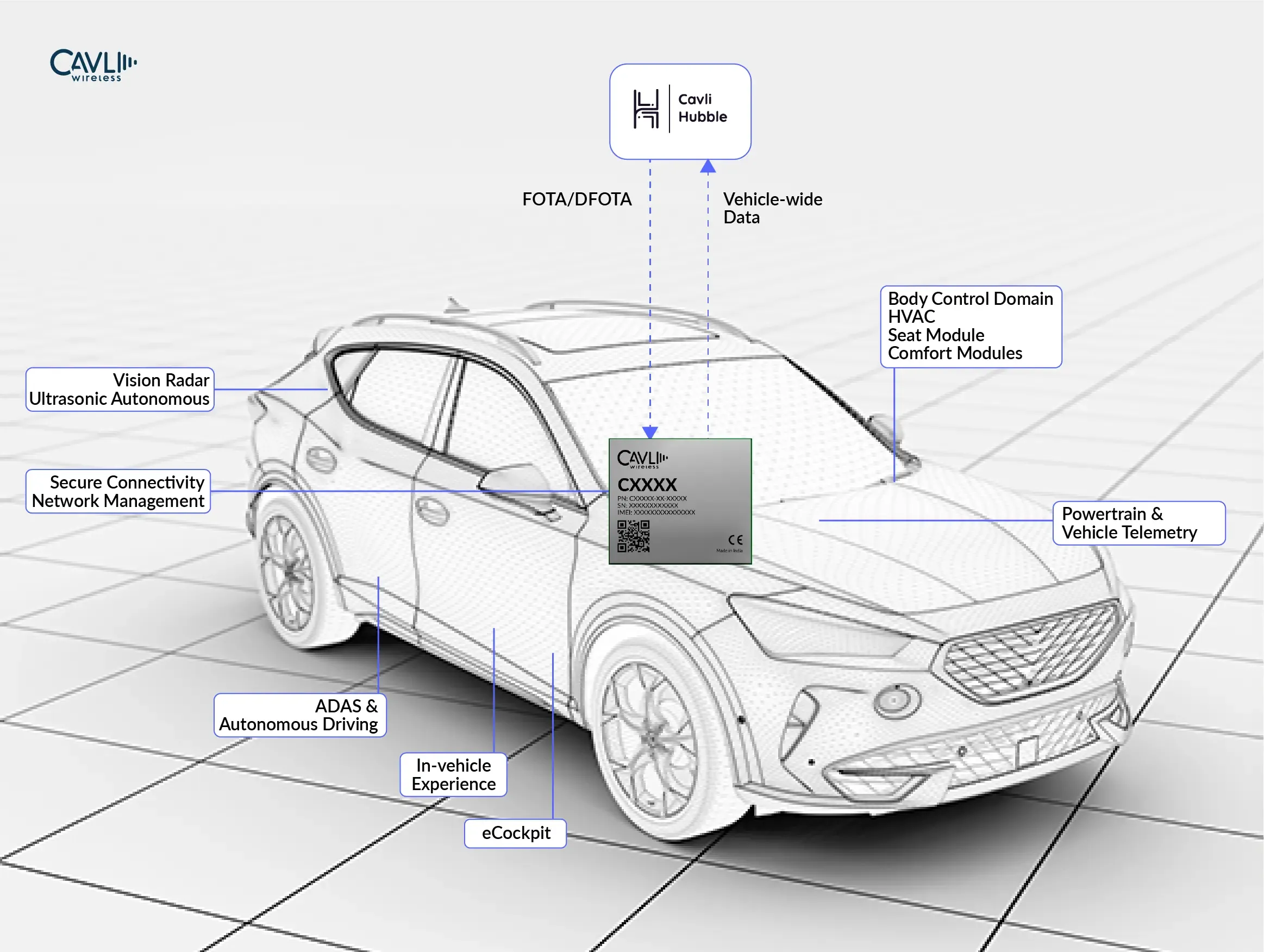

Technical Role of Cavli Smart Modules within Automotive HPC Architectures

Automotive High Performance Computing platforms are designed to execute perception, fusion, planning, and control workloads under strict real-time and safety constraints. However, these centralized HPC systems do not operate in isolation. They rely on distributed edge compute and connectivity nodes to handle data aggregation, external communication, human-machine interfaces, and non-safety-critical processing.

Cavli smart modules, such as CQS290, CQS291, CQS292, and CQS315, function as edge compute and connectivity subsystems within an automotive HPC architecture. Their role is not to replace the central HPC unit, but to offload, support, and extend it in a scalable and power-efficient manner.

1. Connectivity Offload from the Central HPC Platform

One of the key challenges in automotive HPC systems is maintaining continuous external connectivity without burdening the central compute unit with modem control, protocol stacks, and network management.

Cavli smart modules address this by handling:

- LTE Cat 4 cellular connectivity with VoLTE and 2G fallback

- Integrated eSIM management

- Network selection and handover

- Secure data transmission to cloud platforms

By isolating cellular connectivity on a dedicated smart module, the central HPC platform can focus on time-critical tasks such as sensor fusion and control logic. This separation improves determinism and simplifies safety certification of the core compute system.

2. Edge Level Compute for Non-Safety Critical Workloads

Automotive HPC platforms prioritize deterministic execution for safety-critical functions. Tasks such as telemetry formatting, log processing, application-level analytics, and data pre-aggregation are better executed outside the central compute pipeline.

With Quad-Core and Octa-Core processors, Cavli smart modules can:

- Preprocess vehicle telemetry data

- Run application logic on Android or Linux

- Handle diagnostics and health monitoring

- Aggregate data before forwarding to the central HPC or cloud

This reduces compute load and memory contention on the HPC platform, improving overall system stability.

3. GNSS Processing and Location Intelligence

Accurate positioning is a key input for perception and planning systems running on automotive HPC platforms. Rather than consuming HPC resources for GNSS signal handling, Cavli smart modules provide a dedicated positioning subsystem.

Key capabilities include:

- Multi-constellation GNSS support

- L1 and L5 band positioning on CQS292

- High-accuracy location output for navigation and fleet intelligence

The smart module delivers processed location data to the HPC platform over vehicle networks, allowing the HPC system to consume location inputs without managing raw GNSS processing.

4. Human Machine Interface and Display Processing

In modern vehicles, visual interfaces such as instrument clusters, infotainment displays, and driver feedback systems require continuous rendering and application-level logic.

Cavli smart modules support:

- MIPI DSI or LCD DSI display interfaces

- Multiple Camera Support

- GPU-accelerated graphics pipelines

- Android or Linux-based UI frameworks

By managing display and HMI workloads on a smart module, the central HPC platform remains isolated from non-deterministic graphics and application-level rendering tasks.

5. Data Path Optimization in HPC Workflows

Automotive HPC systems rely on predictable data flows. Excessive I/O operations or network interrupts can introduce latency and jitter.

Cavli smart modules improve data path efficiency by:

- Acting as data aggregation points

- Filtering and batching telemetry data

- Managing asynchronous communication with backend systems

This ensures that only relevant, structured data reaches the central HPC unit, preserving real-time performance.

Emerging Trends in Automotive High Performance Computing

Automotive High Performance Computing platforms are evolving rapidly as vehicles transition toward software-defined and autonomous architectures. Several key trends are shaping next-generation HPC designs.

Centralized Vehicle Supercomputers

OEMs are moving toward highly centralized compute platforms that replace multiple domain controllers. These systems deliver significantly higher compute density and simplify software integration across ADAS, infotainment, and vehicle control domains.

Zonal Architectures with Central Orchestration

Zonal compute architectures are becoming standard to reduce wiring complexity and latency. Zonal controllers handle local sensor aggregation while a central HPC node executes perception, fusion, and decision-making.

5G-Enabled Cloud Assisted Intelligence

Integration of 5G enables vehicles to interact with edge and cloud systems for map updates, cooperative perception, and fleet learning while retaining real-time decision making locally.

Closing Notes

Automotive High Performance Computing has become the foundation of modern vehicle intelligence, enabling real-time perception, decision-making, and software-defined functionality. By consolidating compute, optimizing data flow, and separating safety-critical and non-critical workloads, HPC platforms allow vehicles to scale in capability without compromising reliability or safety. As architectures continue to evolve toward centralized and zonal designs, HPC will remain central to delivering intelligent, connected, and future-ready mobility systems.

Amusing Tech Chronicles

Facts and Anecdotes related to this edition of Wireless By Design

The Vehicle Brain and Its Nervous System

Think of the automotive HPC platform as the brain of the vehicle. It processes vision, makes decisions, and controls motion in real time. Cavli smart modules act like the nervous system. They carry signals to and from the outside world, manage communication, and relay precise location data. Just as the brain cannot function without reliable nerves, an automotive HPC system depends on stable connectivity, positioning, and data exchange to operate effectively.

The Control Tower and the Ground Crew

An automotive HPC platform is like an airport control tower. It manages critical decisions such as collision avoidance, trajectory planning, and safety enforcement. Cavli smart modules function as the ground crew. They handle communications with external systems, manage telemetry, operate displays, and ensure that data reaches the right destination without interrupting critical control operations. This separation keeps the control tower focused while the ground crew ensures smooth operations.

The Orchestra Conductor and the Section Leaders

In a modern vehicle, the HPC platform is the conductor coordinating sensors, actuators, and AI models. Cavli smart modules act as section leaders. They manage specific responsibilities such as connectivity, GNSS positioning, and user interfaces. Each section performs independently but stays synchronized with the conductor, ensuring the entire system performs in harmony without timing conflicts.