Introduction

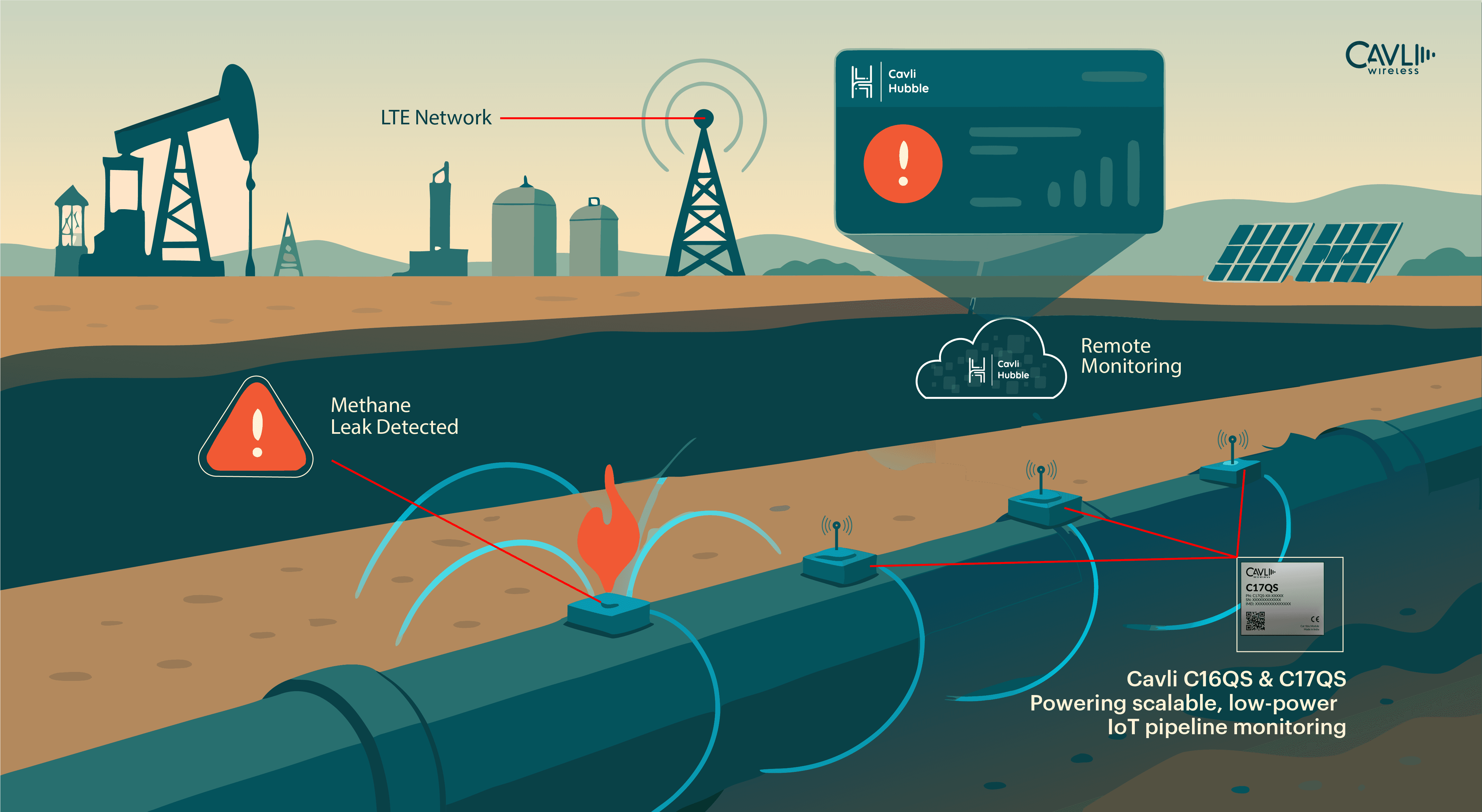

Pipeline monitoring involves continuously tracking the condition and performance of pipelines to ensure safe, efficient, and reliable operations across industries such as water, chemicals, and energy. Within this broader scope, oil and gas pipelines represent a unique subset. They span vast distances, operate under high pressures, and transport hazardous, often flammable materials. These factors make them particularly vulnerable to risks like methane leaks, which not only threaten safety and operational integrity but also contribute significantly to environmental damage.

As a result, monitoring oil and gas pipelines demands specialized approaches that combine advanced detection technologies with rapid response and strict safety standards. Beyond the immediate danger of explosion or ignition, methane is a potent greenhouse gas. Regulatory bodies across the globe are tightening controls, demanding real-time visibility into pipeline emissions and faster response to leakage events. The engineering challenge is complex. Monitoring systems must provide real-time, sub-second detection capabilities, while each sensing node operates under strict power constraints, often in remote or hazardous locations. Cellular coverage can be inconsistent across long pipeline stretches, and maintenance visits are both costly and logistically challenging. Traditional systems struggle to meet all these demands simultaneously: speed, reliability, power efficiency, and scalability.

At Cavli Wireless, we tackle this challenge with a dual solution strategy. By offering both a modular design with the Cavli C16QS and an integrated design with the Cavli C17QS, we enable flexibility for OEMs developing methane detection systems. These two approaches address varying cost targets, integration needs, and deployment scales, without compromising on performance or reliability.

Understanding the Technical Landscape of Methane Detection;

Methane monitoring requires continuous sampling and intelligent processing to differentiate between normal environmental variations and actual leak events. The choice of sensor technology plays a critical role. Electrochemical sensors are valued for their high precision in detecting gases like methane, though they require regular calibration and may drift with prolonged use. Catalytic bead sensors stand out for their durability and ruggedness, but often lack selectivity, making them better suited for general combustible gas detection rather than fine discrimination. Infrared-based sensors, on the other hand, deliver long-term stability, resist cross-gas interference, and require minimal maintenance, making them especially suitable for remote or hard-to-access pipeline deployments.

From an interface perspective, electrochemical and catalytic bead sensors typically output analog signals. These signals require additional conditioning and ADC integration before connecting to an MCU or modem, adding design complexity. Infrared sensors, especially modern NDIR modules, often come with built-in digital interfaces such as UART, I²C, or MODBUS, making them more receptive to direct programming, easier to integrate with microcontrollers, and more flexible for remote telemetry applications.

Edge processing capabilities are equally important. Methane levels fluctuate based on temperature, pressure, and airflow, so a robust detection system must compensate for these changes in real time. Baseline drift correction, dynamic thresholding, and lightweight machine learning models can reduce false positives and improve detection accuracy. Connectivity is another critical component. Each node must reliably transmit alerts and diagnostic data without consuming excessive power. LTE Cat 1bis is well-suited to this task, providing sufficient data throughput, sub-second latency, and broad coverage.

Power-saving modes such as PSM (Power Saving Mode) and eDRX (Extended Discontinuous Reception) are critical for extending the lifespan of battery-powered pipeline monitoring nodes, especially in remote areas where maintenance is difficult. In PSM, the modem stays registered to the network but enters a deep sleep state, often drawing only microamps, waking only for scheduled transmissions or external triggers. eDRX lengthens the paging cycle allowing the device to remain in low-power states longer while still being reachable by, balancing responsiveness with reduced energy consumption. By tuning parameters like the periodic TAU (Tracking Area Update) timer in PSM or the eDRX cycle length, nodes can optimize duty cycles to minimize current draw without losing connectivity. With proper configuration, LTE-M or NB-IoT modules using PSM can achieve multi-year lifetimes on lithium-thionyl chloride batteries with periodic telemetry uploads.

Power management becomes more complex when pairing primary batteries with energy harvesting sources such as solar panels or vibration harvesters attached to pipelines. These hybrid systems require power conditioning circuits, maximum power point tracking (MPPT) for solar input, and supercapacitors or rechargeable buffers to stabilize intermittent energy. A well-designed node maximizes sleep intervals, waking only for sensing and communication, and completes tasks like ADC sampling, signal processing, and secure data transfer within a tightly controlled active window. Remote capabilities are equally important: the ability to update firmware, adjust duty cycles, and monitor metrics like battery health and temperature reduces site visits, lowers costs, and improves resilience against changing operational needs.

Cavli’s Modular and Integrated Approaches

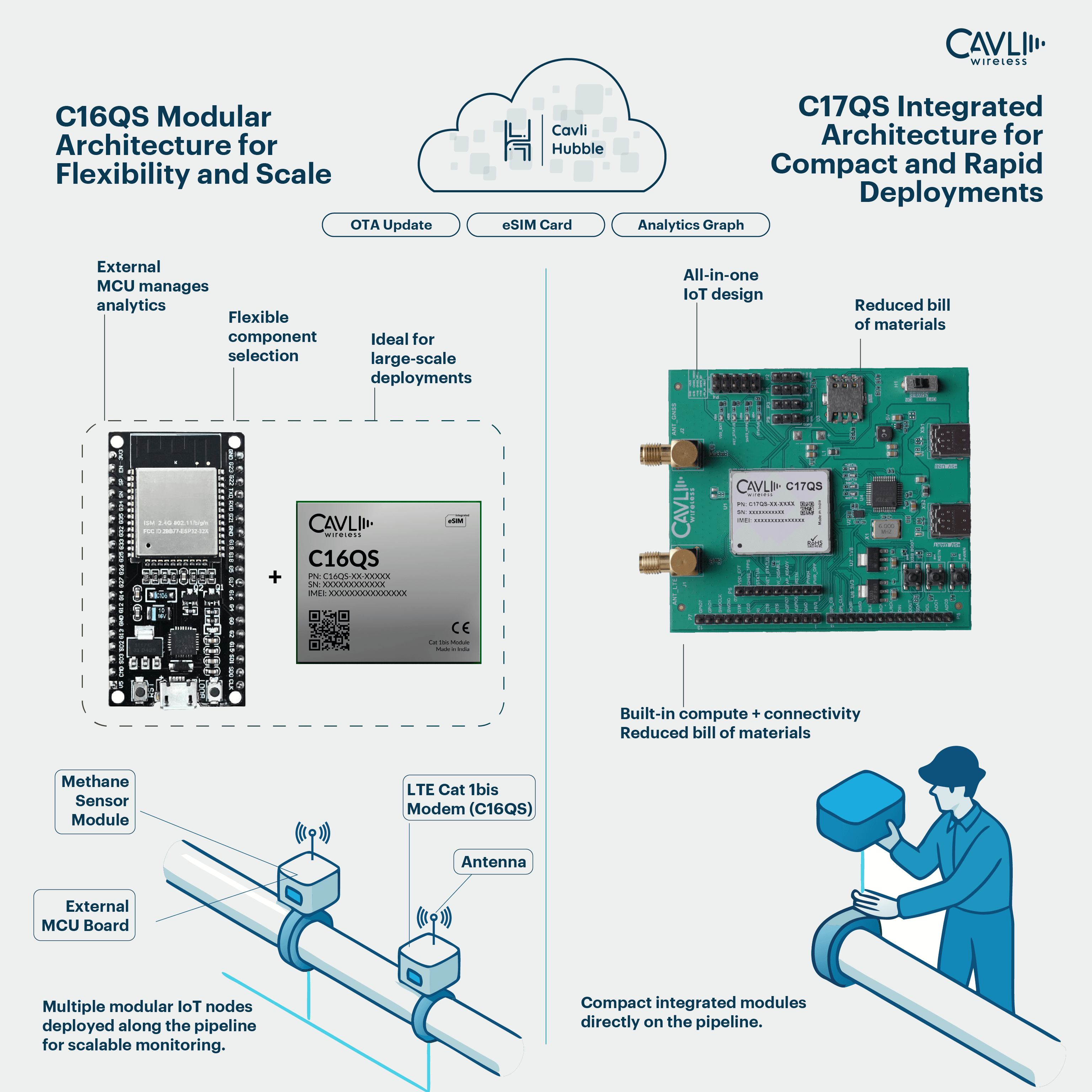

To meet the wide range of deployment scenarios and customer requirements, Cavli Wireless offers two primary solutions: the modular C16QS paired with an external MCU and the integrated C17QS with built-in compute and connectivity. Each approach presents distinct advantages, allowing OEMs to tailor their systems for performance, cost, and complexity.

C16QS with External MCU: Modular Architecture for Flexibility and Scale

The C16QS is a dedicated LTE Cat 1bis modem designed for projects that require hardware flexibility and cost efficiency. In this architecture, the modem handles all cellular connectivity functions, while an external microcontroller (MCU) manages the sensor interface, data processing, and edge analytics. This separation allows for optimal component selection tailored to specific application needs.

For example, if a pipeline monitoring application requires advanced AI-based anomaly detection, a higher-performance MCU can be selected without impacting the connectivity component. Additionally, this approach supports easy upgrades or changes in sensor technology, as the sensing logic remains independent of the modem. It is especially beneficial in large-scale deployments where minimizing cost per node is critical, and hardware reuse is desired across multiple product versions.

The C16QS integrates seamlessly with the Cavli Hubble platform. This enables remote provisioning, eliminating the need to manually manage SIM cards across thousands of nodes. Device health monitoring, diagnostics, and connectivity management are centralized, reducing operational overhead. With global certifications and integrated eSIM support, the C16QS offers true one-SKU deployment for international projects.

C17QS: Integrated MCU and Modem for Compact and Rapid Deployments

For applications where space is constrained or development speed is a priority, Cavli offers the C17QS, a highly integrated LTE Cat 1bis module. This all-in-one design reduces the bill of materials, simplifies PCB layout, and speeds up time to market.

Equipped with 2 MB of RAM and 8 MB of flash storage, the C17QS provides ample memory for sensor drivers, edge analytics, and communication protocols. It supports a wide range of interfaces, including UART, I²C, SPI, USB, and GPIOs, allowing direct connection to methane sensors and other peripherals. The module also offers GNSS capabilities, enabling location-aware detection and alerting.

The primary advantage of the C17QS is its simplicity. A single firmware image controls both sensing and communication, eliminating the need for complex inter-module coordination. Power management is simpler, and debugging is easier with fewer components involved. This makes the C17QS ideal for OEMs looking to build compact, reliable, and easily scalable devices with minimal integration effort.

Like the C16QS, the C17QS is deeply integrated with Cavli Hubble, supporting over-the-air updates, real-time telemetry, and multi-region network management. This ensures long-term maintainability and adaptability in dynamic field environments.

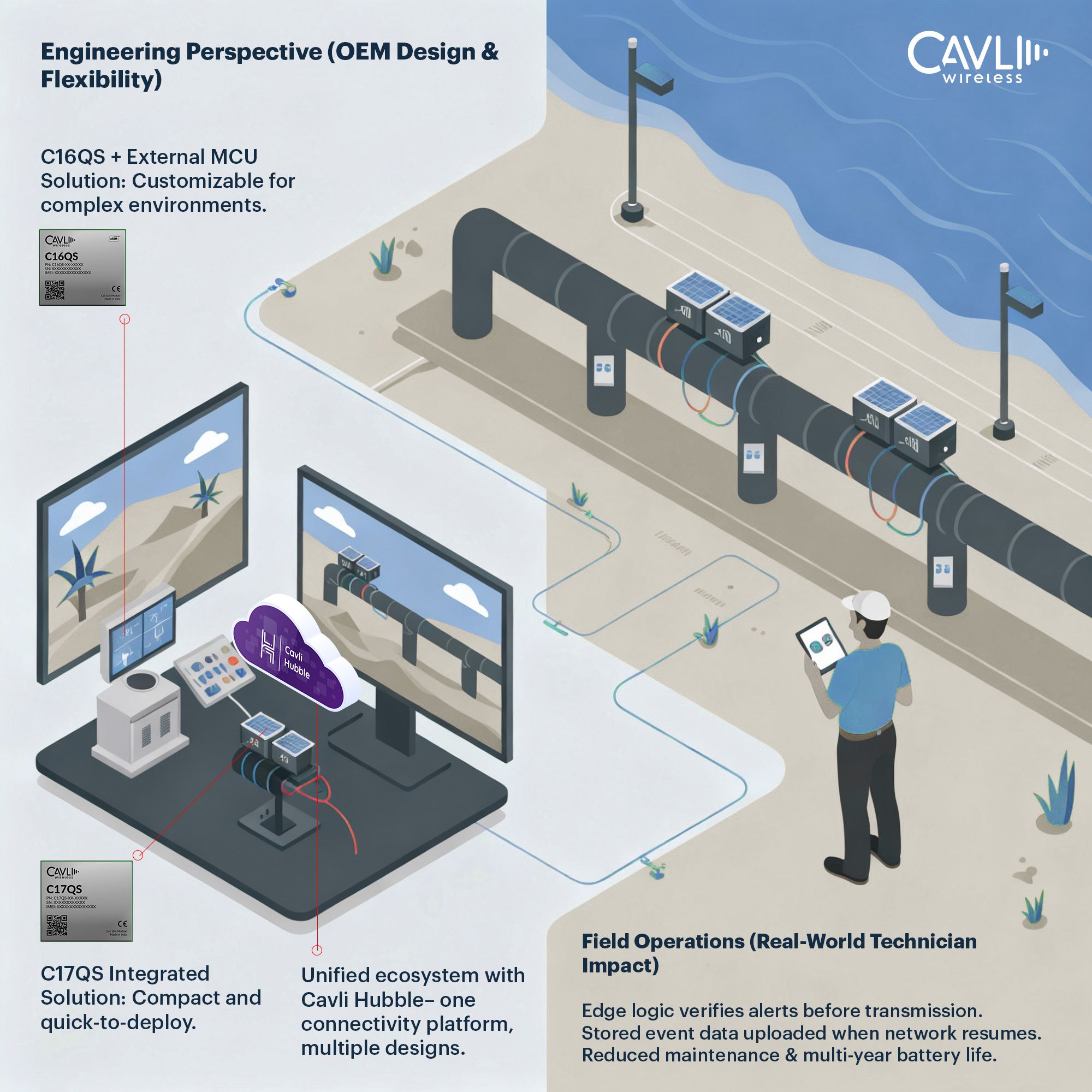

Engineering Implications for OEMs

For OEMs, pipeline deployments resemble building a modular toolkit where flexibility is key. Imagine a systems integrator designing for two very different regions: a desert pipeline with high solar availability and a coastal pipeline prone to corrosion and requiring heavier data processing for predictive analytics. With the modular C16QS plus MCU approach, the integrator can swap in a high-performance MCU for the coastal project while keeping the same connectivity module, avoiding a full redesign. In contrast, for desert deployment, the integrated C17QS offers a sealed, compact design that is simpler to certify and deploy quickly.

This dual solution strategy is like a technology company deciding whether to roll out a configurable enterprise server for a demanding client or a compact pre-built workstation for a small office. Both options are supported under the same ecosystem, giving OEMs the flexibility to serve diverse customer needs. This reduces time to market, simplifies supply chains, and ensures regulatory compliance across regions.

Real-World Impact on Equipment Operators and Field Technicians

For operators in the field, Cavli-powered nodes deliver fewer surprises and enhanced reliability. Consider a technician overseeing a 200-kilometer stretch of pipeline in a remote area with spotty cellular coverage. If a leak occurs, the node automatically enters high-alert mode, increases sampling frequency, verifies the event with edge logic, and transmits an immediate alert once connectivity is restored. This process is similar to a black-box flight recorder that securely stores critical data during turbulence and uploads it upon landing, ensuring no crucial events are missed.

Technicians also benefit from reduced maintenance burdens. It's like upgrading from a vehicle that constantly requires manual oil checks to one that automatically sends health reports to the driver’s phone. Combined with multi-year battery life supported by solar or energy during vibration harvesting, this drastically lowers field visits. The result is safer, more predictable, and more cost-effective operations.

Operational Benefits and Cavli’s Competitive Edge

Both solutions offer key technical and operational advantages. Real-time responsiveness ensures that leaks are detected as soon as they occur, not minutes or hours later. With deep power-saving capabilities, Cavli-powered nodes can operate for months or even years on a single battery, depending on usage patterns and energy harvesting methods.

Cavli’s global connectivity support simplifies international deployments, allowing the same device to be used across different regions without requiring multiple SKUs. This is a major advantage for multinational oil and gas operators seeking consistency and scalability.

Remote management through Cavli Hubble reduces maintenance costs through centralized device oversight. Fleet-wide diagnostics, provisioning, and firmware updates are handled from the cloud, eliminating costly on-site visits.

From a business perspective, Cavli’s dual-solution strategy empowers OEMs to optimize for cost, performance, or design simplicity without being locked into a one-size-fits-all approach. This flexibility, combined with global certifications and robust security, makes Cavli a compelling partner for industrial IoT deployments in critical infrastructure sectors.

Conclusion

Real-time methane detection in pipelines is a mission-critical application that demands fast, reliable, and energy-efficient solutions. With Cavli’s modular C16QS and integrated C17QS architectures, IoT device makers have the tools they need to design systems that are both scalable and cost-effective. Whether optimizing for flexibility or simplicity, these modules provide robust connectivity, long battery life, and seamless integration with remote management platforms.

Cavli’s technology enables safer, greener, and more responsive pipeline operations. To explore how our solutions can help your IoT product roadmap, get in touch with our team or explore our developer resources to start building today.