Unplanned downtime in large-scale IoT implementations poses a significant challenge for operators, often leading to operational disruptions. Traditionally, maintenance has been reactive, addressing issues only after they manifest. However, the advent of advanced data analytics and IoT connectivity has transformed this approach, enabling the implementation of predictive maintenance systems.

Today, the extensive amount of data generated by these complex systems can be actively leveraged to significantly reduce downtime. By analyzing this data, organizations can detect nascent issues and anticipate maintenance requirements long before they develop into critical failures. This strategy allows for scheduled interventions, minimizing service interruptions and maximizing system availability.

Historically, the sheer volume of data and the computational power required for sophisticated analysis made predictive maintenance impractical. However, modern IoT deployments now put an active effort to integrate it into their operational pipeline. This integration empowers operators and engineers with real-time insights into system health and functionality, enabling them to track, monitor, and address potential problems. The shift from reactive to predictive maintenance not only optimizes operational efficiency and extends asset lifecycles but also significantly mitigates the risks associated with unforeseen outages. Cavli's suite of IoT solutions, especially the CQS315 module, is designed to enable seamless and intelligent connectivity for a wide range of industrial applications. The limitations of cloud-centric predictive maintenance architectures are addressed by the implementation of edge computing solutions.

Challenges of High Latency and Unreliable Connectivity in IoT-Based Predictive Maintenance

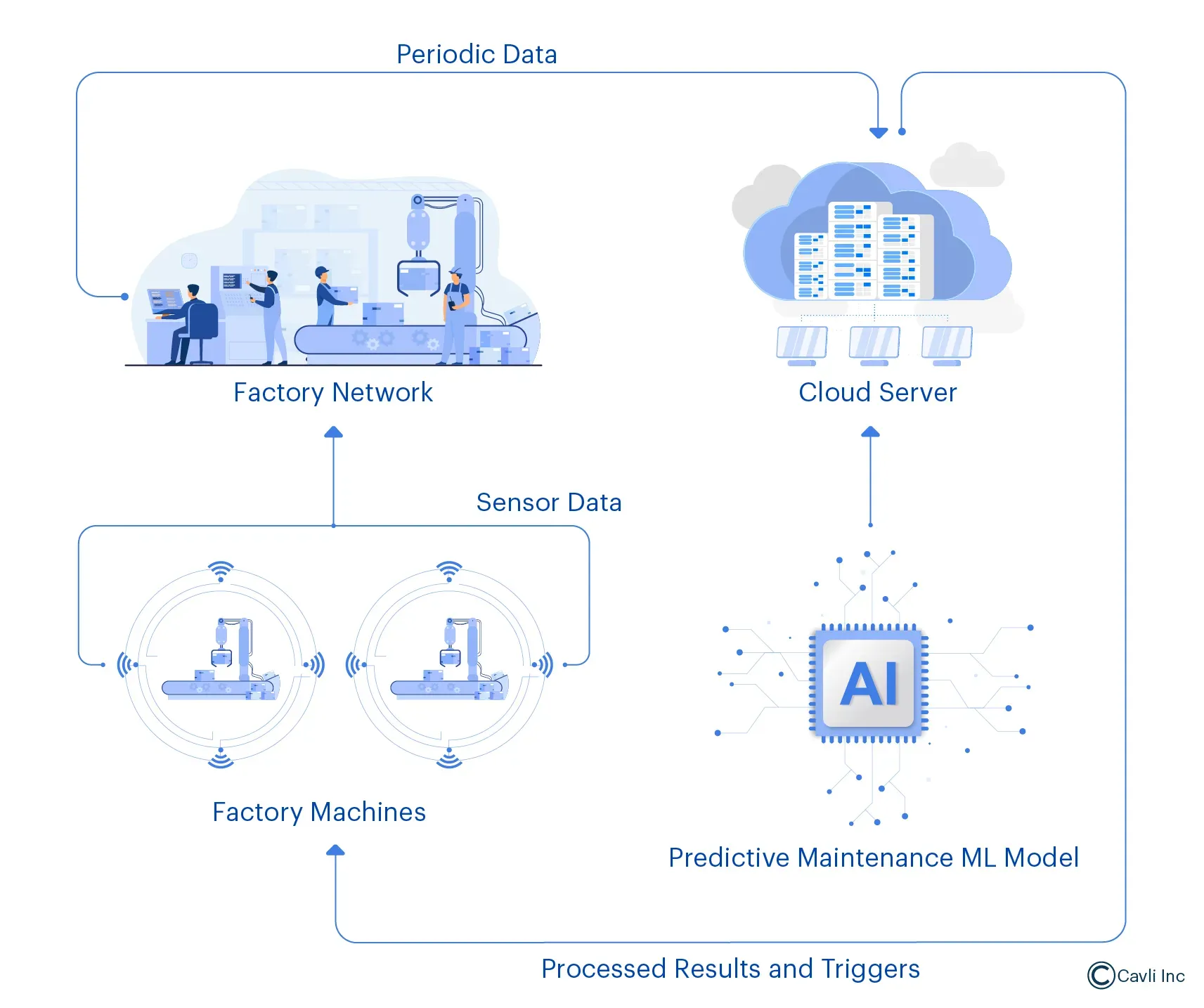

In traditional predictive maintenance architectures, sensor data from machines or assets is continuously streamed to centralized cloud servers, where the data is processed, analyzed, and predictions are generated. While this centralized approach works well in stable environments, real-world IoT deployments are far more diverse and often less forgiving. When applying a purely centralized architecture to many real-world IoT use cases, we encounter significant limitations that can severely hamstring the effectiveness of predictive maintenance. These aren't minor hiccups; they are fundamental obstacles that necessitate a rethinking of how we process and analyze critical asset data.

The Cloud Conundrum: Why Centralized Systems Struggle

In a centralized architecture, the dependence on continuous data transmission to a cloud-based system presents significant challenges for implementing predictive maintenance in many IoT environments.

Primarily, network latency and delays pose a critical problem. Industrial assets generate large amounts of raw sensor data (e.g., vibration, temperature, pressure) at high frequencies. Transmitting this data over wide-area networks, particularly via cellular or satellite connections, can introduce significant delays, ranging from seconds to minutes. This lag between data generation and insight acquisition can be detrimental in predictive maintenance, where even minor delays may cause critical early failure detection windows to be missed, making the analysis less effective than real-time diagnostics.

Intermittent or unstable connectivity in remote and harsh deployment environments, such as mines, rural industrial sites, or mobile assets, leads to unreliable data streams and potential data loss or accumulation. This scenario disrupts timely analysis and creates data backlogs when connectivity is restored. Further compounding the issue are bandwidth constraints and high transmission costs, as continuously streaming large amounts of raw sensor data is financially unsustainable, especially over metered cellular or satellite networks with limited bandwidth. Finally, transmitting sensitive operational data over public networks raises substantial security and privacy concerns, expanding the attack surface and complicating compliance with data governance regulations.

CQS315: Bringing Intelligence to the Edge

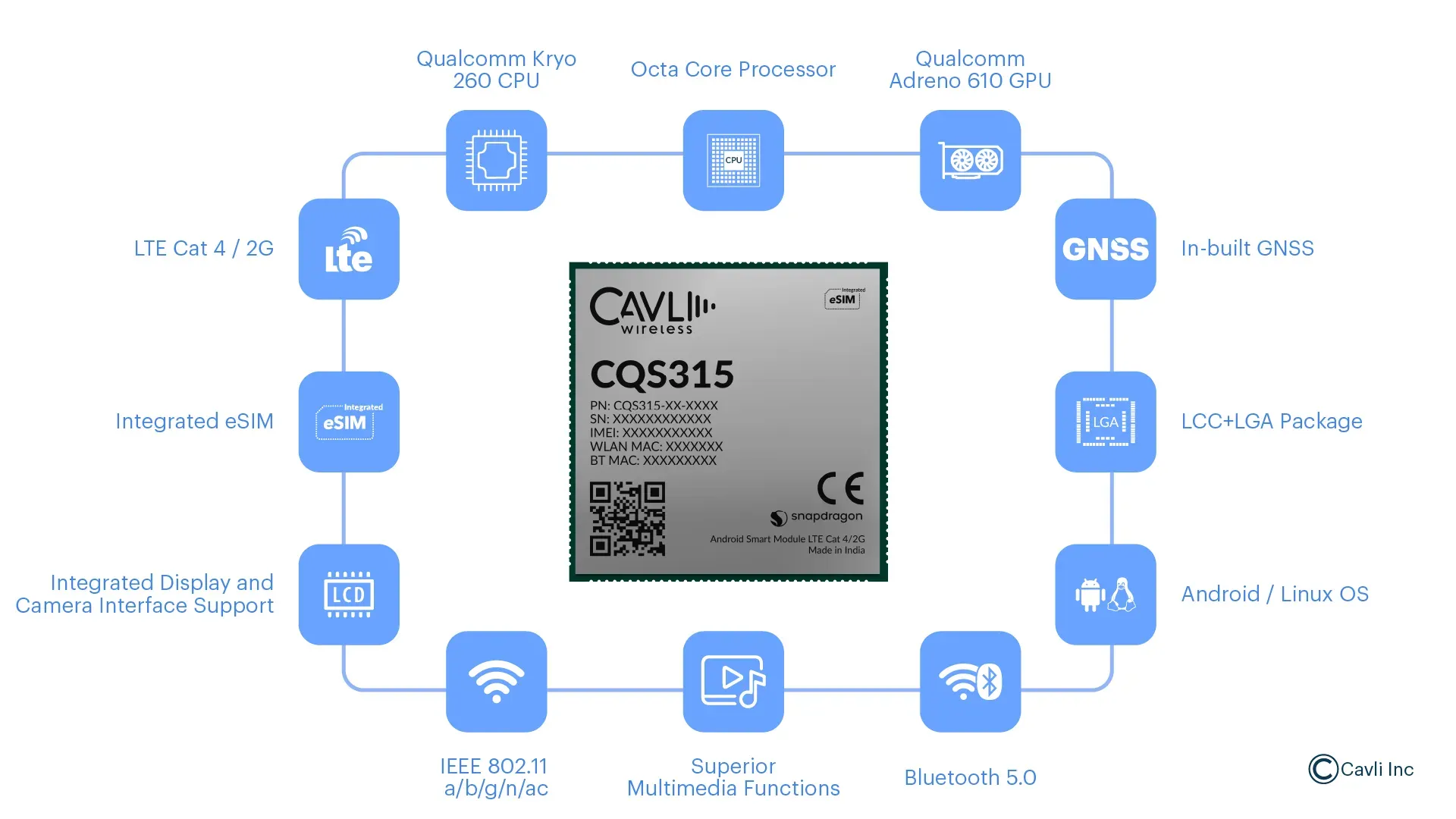

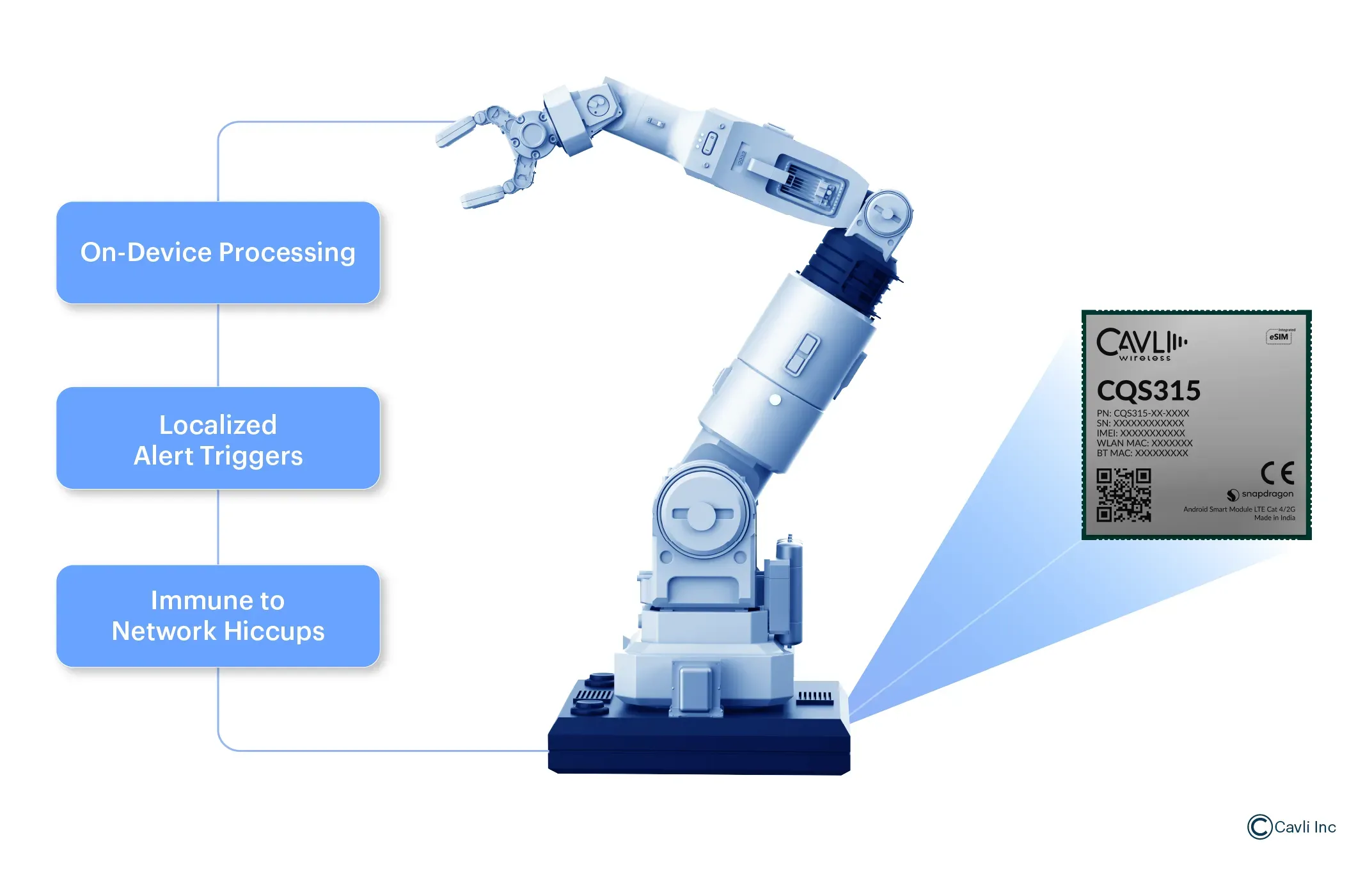

The Cavli CQS315 shifts the processing intelligence closer to the data source, transforming how critical asset data is analyzed and utilized. A key advantage of the CQS315 lies in its ability to overcome network latency and delays. Equipped with a powerful Qualcomm Octa-core Kryo 260 64-bit CPU and an Adreno 610 GPU, the module can run predictive maintenance algorithms directly on the device.

On-device processing facilitates the real-time analysis of high-frequency sensor data, such as vibration, temperature, and pressure, allowing immediate detection of anomalies without the inherent delays of transmitting raw data to and from a centralized cloud server. This real-time capability is crucial for identifying potential failures within the narrow window required for proactive intervention.

This edge processing capability also significantly reduces bandwidth usage and associated costs by enabling the CQS315 to analyze raw sensor data locally and transmit only critical alerts or summarized insights to the cloud, making deployments more cost-effective, especially over metered cellular or satellite networks.

By keeping raw sensor data on-device and transmitting only essential information securely, the module enhances security and privacy. This localized data handling simplifies compliance with data privacy regulations, addressing a critical concern in transmitting sensitive operational data over public networks.

Seamless Connectivity and Uninterrupted Monitoring with the Cavli CQS315

The CQS315 is engineered to handle intermittent or unstable connectivity that often plagues remote or mobile IoT deployments. Its multi-modal connectivity options—including LTE Cat 4 cellular with 2G fallback, dual-band Wi-Fi, Bluetooth 5.0, along with the optional integrated eSIM capability, allow it to automatically adapt to the best available network across regionalities. Even in the event of connection drops, local data processing continues uninterrupted, ensuring continuous monitoring with no blind spots.

Engineering Implications for OEMS

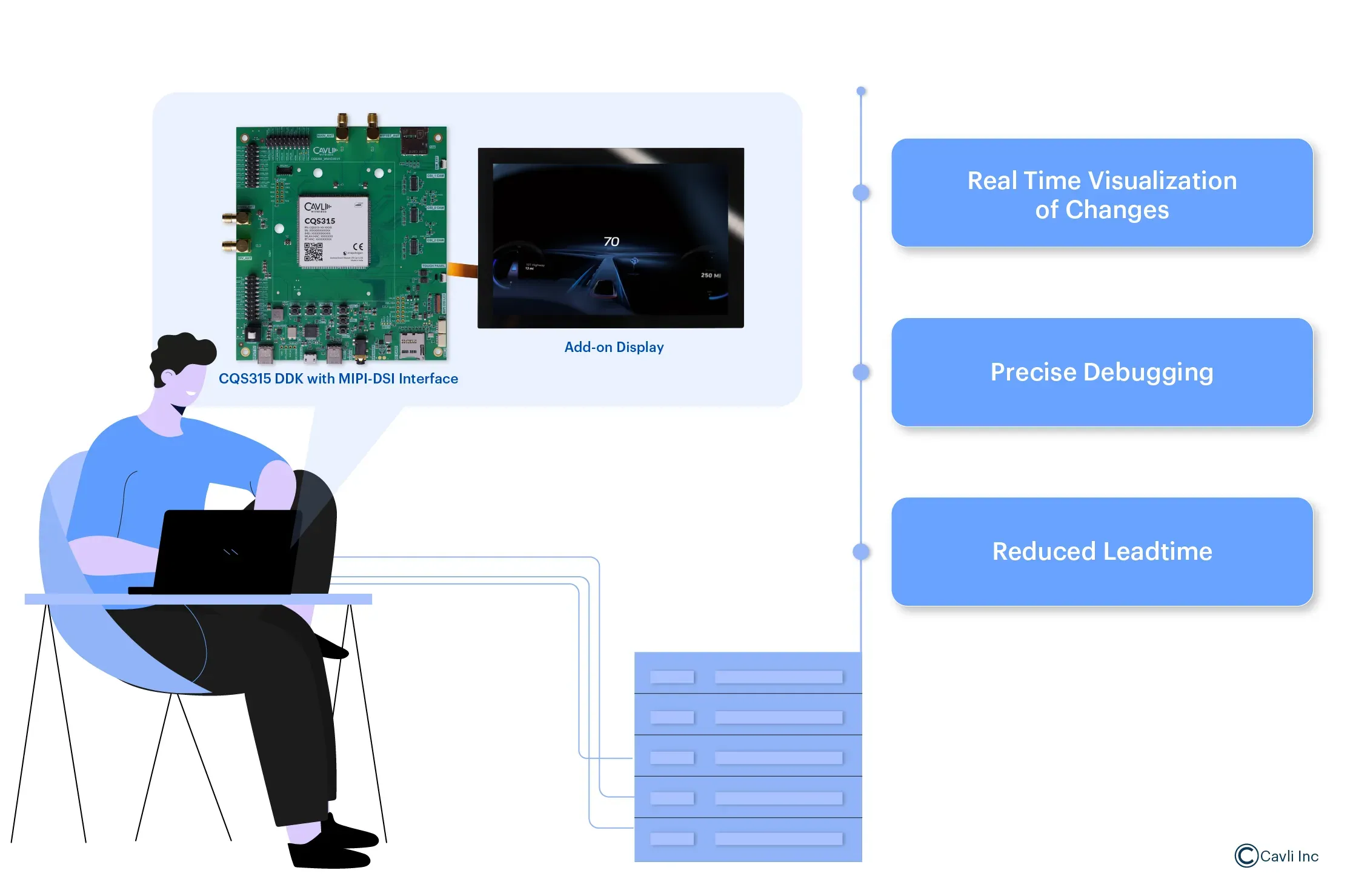

The CQS315 module provides a comprehensive toolkit, including a robust Device Development Kit (DDK) and a multitude of readily available interfacing options and pins. This rich environment grants engineers unparalleled flexibility for rapid experimentation and implementation, thereby substantially reducing the overall lead time in the development cycle.

For example, an OEM designing a telematics-based predictive maintenance system may require the integrated MIPI DSI (Display Serial Interface), which supports full HD resolution, as a crucial visualization tool. This allows engineers to instantly display and interpret real-time data changes, such as vibration patterns or sensor readings, directly on an attached LCD. This immediate visual feedback facilitates faster iteration and precise debugging of complex predictive algorithms on the device itself. This capability ensures that the final deployed solutions are highly refined and optimally performant.

Real-World Impact on Equipment Operators and Field Technicians

For public transportation fleets, even in urban areas, intermittent network coverage can cause cloud-based predictive maintenance systems to miss critical engine or transmission data, potentially leading to mid-route breakdowns. However, with the CQS315 onboard, the system continuously analyzes data locally. This edge processing allows faster, real-time processing of sensor data, detecting anomalies such as unusual engine temperatures immediately. This also means lower amounts of data is transmitted, as only prioritized, compressed messages and critical alerts are sent to the depot when connectivity is available, rather than continuous raw data streams.

Consider a scenario in an automotive factory, where a critical robotic arm on the assembly line is exhibiting subtle, intermittent vibrations that can be interpreted as a precursor to a major malfunction. In a traditional cloud-dependent setup, high-frequency data bursts can be lost due to micro-outages in the factory's Wi-Fi network or latency spikes during peak data traffic.

With the CQS315, we can continuously process the vibration data locally. The system can immediately detect the anomaly, even during brief network hiccups, and trigger a localized alert through other wired peripheral communication protocols and haptics powered by the I2C interface within the module. The maintenance team can then be notified proactively, allowing them to replace a worn bearing during scheduled breaks. This can avert a costly line stoppage that might idle hundreds of workers and cost the company hundreds of thousands of units in lost production.

Closing Notes

The shift from reactive to predictive maintenance in large-scale IoT deployments is crucial for minimizing downtime and optimizing operational efficiency. While traditional cloud-centric architectures face significant hurdles due to latency, unreliable connectivity, and high data transmission costs, edge computing solutions like Cavli's CQS315 module offer a powerful alternative. By bringing processing intelligence closer to the data source, the CQS315 enables real-time analysis, reduces bandwidth consumption, enhances security, and ensures continuous monitoring even in challenging environments. This innovative approach not only empowers operators and engineers with immediate insights but also allows for proactive interventions, ultimately extending asset lifecycles and mitigating the risks associated with unforeseen outages in diverse industrial applications.