In the world of massive IoT, the initial deployment is just the beginning of the journey. For Original Equipment Manufacturers (OEMs) and the enterprises they serve, the true challenge lies in the long-term lifecycle management of thousands, or even millions, of connected devices spread across the globe. The Achilles' heel of many deployments is the "last mile" of device maintenance: firmware updates, bug fixes, and most critically, recovery from catastrophic failures.

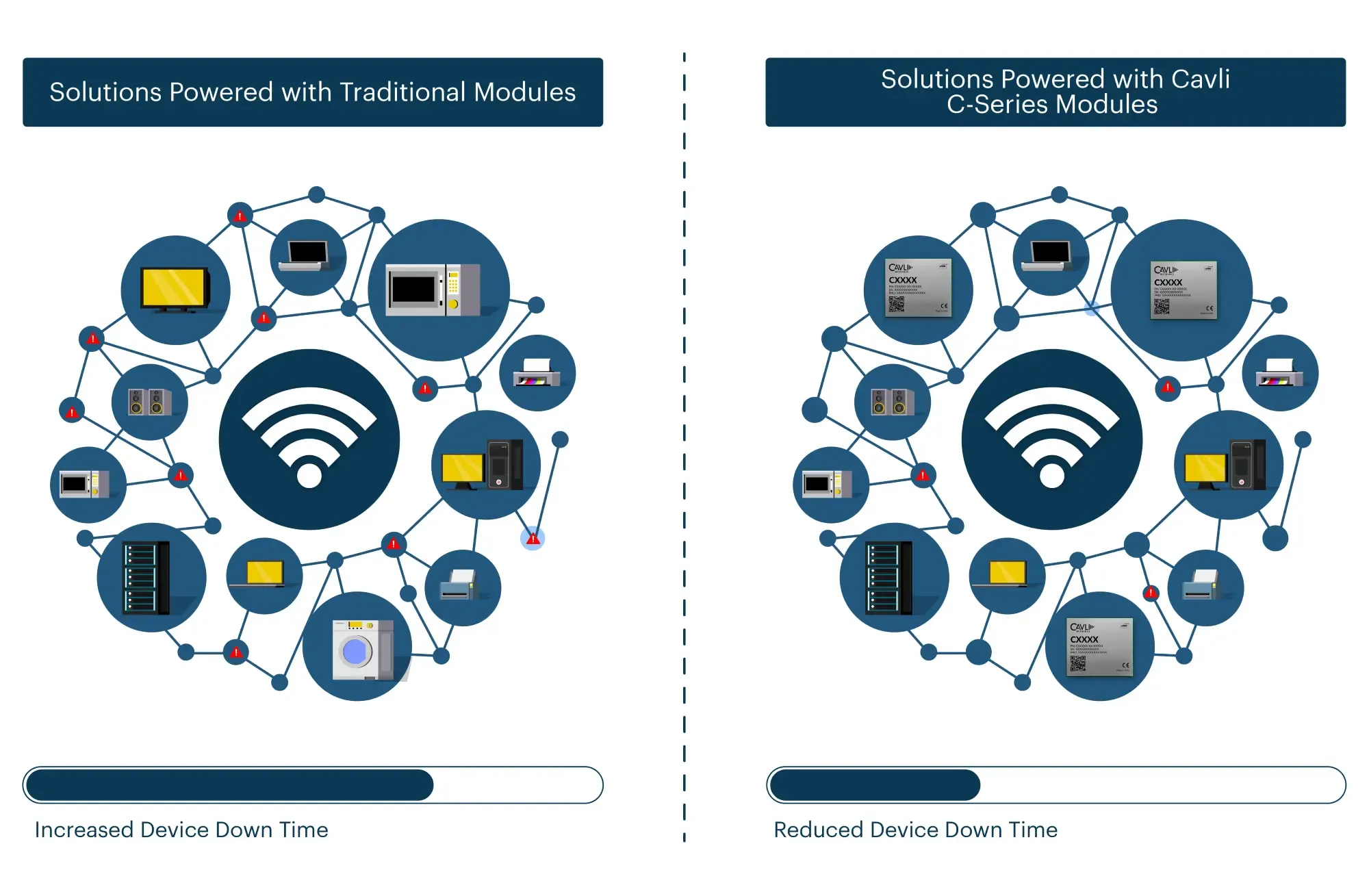

Traditional device flashing processes are often rigid, platform-dependent, and time-consuming. They can create significant bottlenecks in high-volume manufacturing lines and turn field-servicing into a logistical challenge requiring specialized equipment and highly trained technicians. This friction leads to increased operational costs and, most damagingly, device downtime. In an ecosystem where uptime is paramount, how can you build solutions that are not just smart but also fundamentally resilient?

Introducing the Cavli C-Series: Built for Global Performance and Serviceability

Cavli Wireless addresses this challenge head-on with its versatile C-Series lineup of Cat 1 / Cat 4 IoT modules. These modules are engineered to provide robust, reliable, and seamless global connectivity across a wide range of applications, from asset tracking and smart metering to automotive telematics and smart city infrastructure.

At their core, C-Series IoT modules are designed for effortless global deployment, featuring an integrated eSIM and native support for the Cavli Hubble™ connectivity and management platform. This powerful combination handles the complexities of network access and subscription management across over 150 countries. Currently, the focus for this blog is Cavli’s Cat 1 and Cat 4 Modules, which are mainly based on the Qualcomm MDM9207 platform.

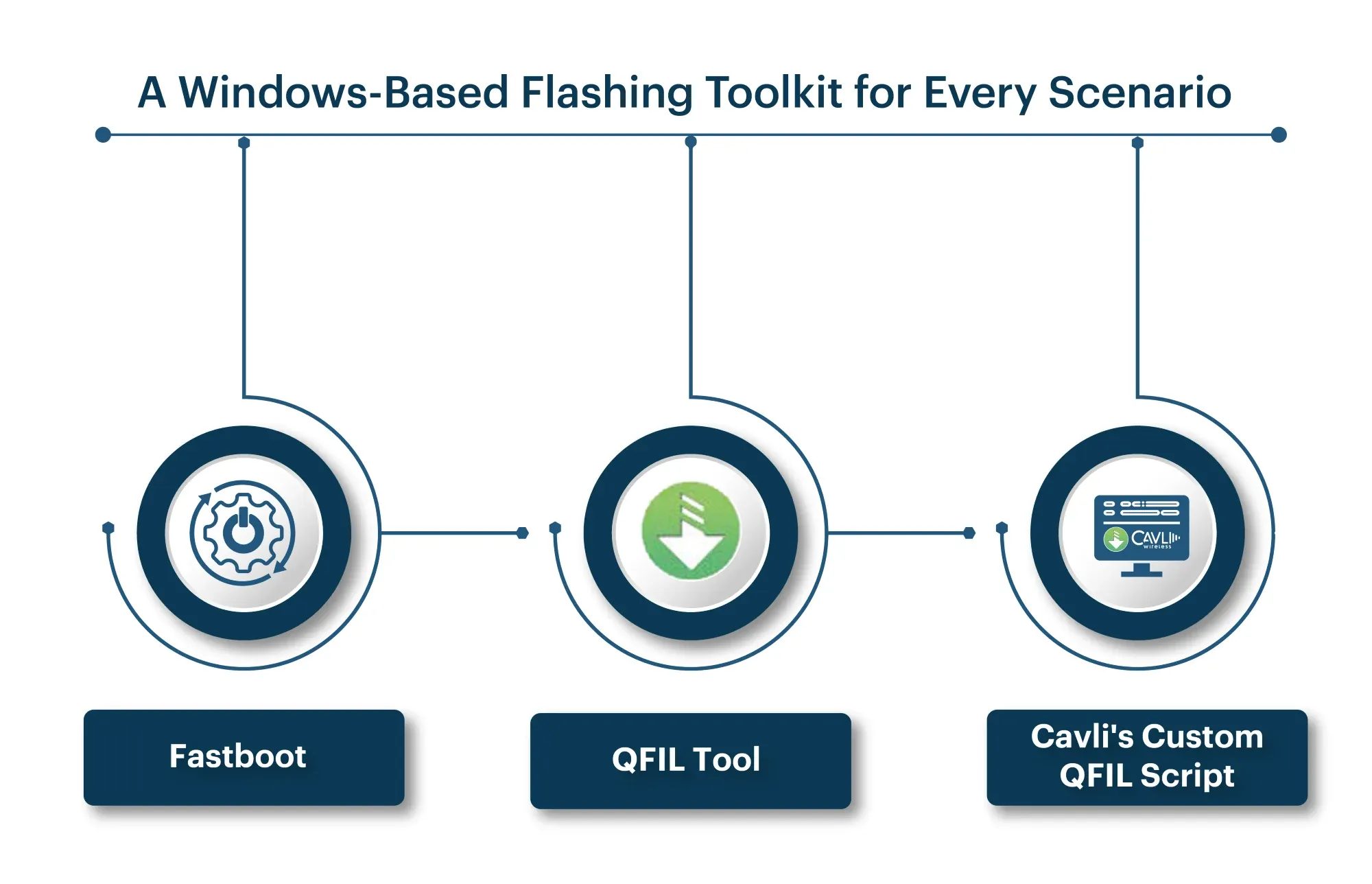

The EDGE Feature: A Windows-Based Flashing Toolkit for Every Scenario

To empower our customers, Cavli has engineered a unique and powerful three-tiered flashing methodology for its Cat 1 and Cat 4 modules, namely the C10QM, CQ10, C11QM and C20QM, CQ20 respectively, all operating on the ubiquitous Yocto Linux platform. As far as flashing such modules using a machine that runs on Windows, these are the strategies that Cavli’s engineers have made available for our customers:

- Fastboot: This is the embedded developer's preferred open-source tool for rapid iteration. It's designed to flash specific binaries and partitions quickly, without requiring a full firmware wipe. It's perfect for the R&D phase when testing small, incremental changes.

- QFIL Tool (in QPST): Qualcomm Flash Image Loader is a comprehensive diagnostic and recovery powerhouse, available as part of the Qualcomm Product Support Tools (QPST) suite, QFIL enables a full "bare-metal" firmware flash, QCN (Qualcomm Calibration Network) file backup and restoration, and generates detailed logs essential for deep-dive debugging of critical issues.

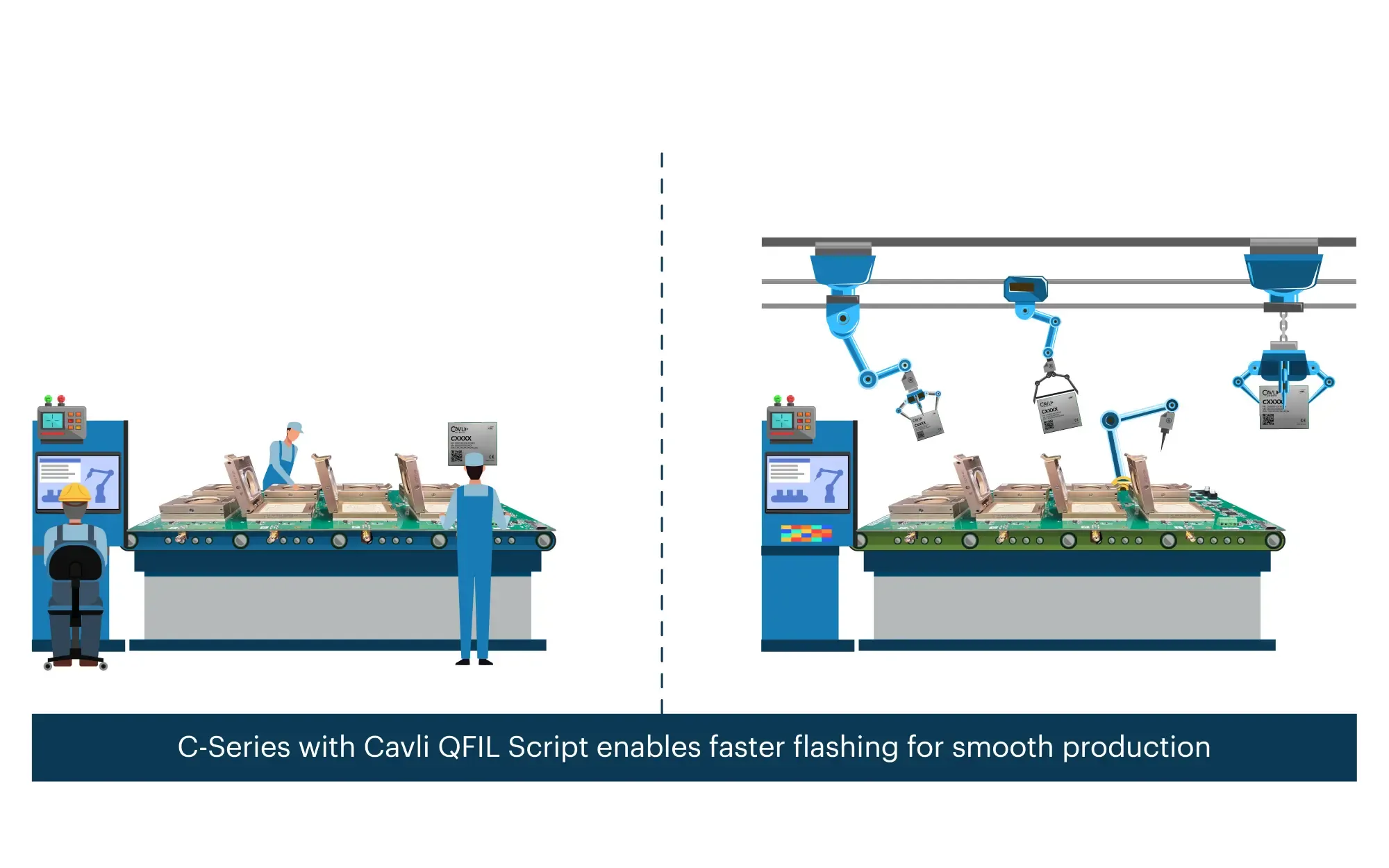

Cavli's Custom QFIL Script: This is our proprietary script for high-volume manufacturing. Developed in-house by Cavli, this optimized script can flash a module, including the QCN, directly in Emergency Download Mode (EDL). With lightning-fast flash times of 6-8 seconds per module, it dramatically accelerates production line throughput.

Combined with robust FOTA (Firmware Over-The-Air) and, on select modules, DFOTA (Delta FOTA) support via the Hubble platform, this toolkit ensures that physical intervention remains a last, but incredibly powerful, resort.

Engineering Implications: The Right Tool for Every Job

To understand the impact of this toolkit, let's consider a practical use case. Consider the case when an OEM is developing a cold chain logistics tracker designed for global pharmaceutical shipments.

- Phase 1: Development & Iteration - The OEM’s engineers are fine-tuning the tracker's temperature-sensing algorithm. They need to test dozens of minor firmware adjustments daily. Instead of a slow, 5-minute full re-flash for every change, they use Fastboot. Pushing only the updated binary takes seconds. This is the difference between a software developer being able to "hot-reload" a feature versus having to recompile an entire application. The result? Their development cycle is accelerated by orders of magnitude.

- Phase 2: High-Volume Manufacturing - The OEM receives an order for 200,000 trackers. Their manufacturing line needs to be a model of efficiency. Manually flashing each device with a standard tool would be a crippling bottleneck. Here, they deploy Cavli's custom QFIL Script. The operator simply connects a batch of modules, and the script automates the flashing process in Emergency Download mode, completing each device in under 8 seconds. This turns the flashing station from a bottleneck into a high-speed, seamless part of the assembly line, enabling them to meet their demanding production targets.

- Phase 3: Critical Field Recovery - A year later, a small batch of 50 trackers in South America goes offline. A software bug has corrupted their memory, causing a persistent bootloop that FOTA updates cannot fix. The cost of shipping these units back for repair is prohibitive. Instead, a local field technician with a Windows laptop is dispatched. Using the QFIL Tool, they force the bricked devices into EDL mode and perform a full firmware recovery, restoring them to a bootable state. Now, to identify the root cause, the technician uses Fastboot to rapidly cycle between recent firmware versions on a test device, quickly isolating the problematic build. A complex international logistics problem is solved in an afternoon.

Practical Implications: The End-User's Experience of Uninterrupted Service

The end-user in this case, the pharmaceutical company, never sees the complexity behind the scenes. They only experience the result: unwavering reliability.

- Maximized Uptime: Users primarily experience updates through seamless FOTA/DFOTA updates, which occur in the background within the modem without causing disruption. They remain unaware of the powerful recovery tools in place, because for 99.9% of cases, they are never needed. Their cold chain data remains consistent, and their compliance is never in question.

- Trust and Confidence: For the 0.1% of devices that fail critically, what users experience is not a problem, but a swift solution. Instead of being told that a critical tracker is "dead" and needs replacement, a process that could take weeks and jeopardize a valuable shipment, they are informed that the device was "remotely serviced" and is back online within hours. This transforms a potential catastrophe into a demonstration of both the product's resilience and the OEM's excellent support.

Ultimately, the pharmaceutical company would rarely be bothered about QFIL scripts or Fastboot. They care that their life-saving cargo is monitored in real-time, without interruption. Cavli’s multi-faceted flashing toolkit empowers OEMs to deliver on that promise of absolute operational continuity.

Closing Notes

As we've explored, the often-overlooked phase of device management is high-speed production flashing to critical field recovery that can make or break the viability of a massive IoT deployment.

Cavli’s C-Series modules directly address this with a multi-faceted approach. The powerful combination of a high-speed custom QFIL Script for manufacturing, the agility of Fastboot for development, and the comprehensive recovery capabilities of the QFIL Tool, all on the accessible Windows platform, forms a complete toolkit for every stage of a product's life. When integrated with the Cavli Hubble™ modem management platform, this toolkit provides a resourceful strategy that empowers OEMs to minimize downtime, accelerate time-to-market, and build products that inspire confidence.

Ultimately, this is our engineering philosophy in action: providing not just components, but complete, well-thought-out solutions that anticipate and solve the real-world challenges our customers face. It’s a clear demonstration that a truly smart IoT solution isn't just about connecting a device; it's about engineering the tools to keep it connected, resilient, and reliable for its entire lifecycle.